On-cell: Indicates that the touch layer will be above the liquid crystal

and refers to the method of embedding the touch screen between the color filter and polarizer of the display screen. It means the touch sensor is equipped on an LCD panel, which is much less difficult than in Cell technology

In-Cell: It refers to the method of embedding the touch panel function into the liquid crystal pixels, it means embedding the touch sensor function inside the display screen, which makes the screen thinner and lighter.

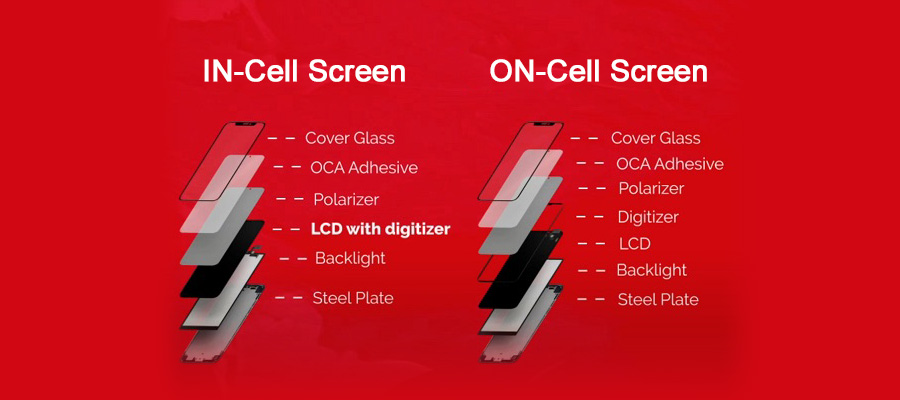

To thoroughly understand screens such as In-Cell/On-Cell, you must first understand the basic structure of the screen. It can be clearly understood from the figure above that the structures of in-cell and on-cell are similar. In both touchscreen solutions, there is a protective glass on the top to protect the touch screen and LCD panel. The obvious difference is that in-cell is to build the touch screen layer into the LCD panel, while on-cell is to make the touch screen layer on the LCD. Due to the difference in touch technology, the screen of an in-cell phone is thinner than that of an on-cell.

In-Cell and On-Cell have different structures, different screen brightness, different display effects, different manufacturing costs and different yields:

- In terms of screen transparency and visual effects, In-Cell and On-Cell screen transparency and visual effects are not much different.

- Thickness. Generally speaking, In-Cell is the lightest and thinnest. This is also one of the reasons why the iPhone uses a metal body and can still be extremely thin and light. On-cell is slightly worse than in-cell.

- Screen strength (impact resistance, drop resistance), On-Cell is better than In-Cell.

- In terms of touch, the In-Cell screen directly fuses the touch layer with the liquid crystal layer, and the induced noise is relatively large, which requires a special touch chip for filtering and correction processing.

- In terms of yield, with the continuous investment of manufacturers and the maturity of technology, the yield rate of In-Cell/On-Cell screens has been at the same level, and large-scale shipments are not a problem.